Who we are

Our Mission is to constantly improve the methods and the quality of construction processes through research, innovation and cooperation with designers, engineers and contractors worldwide.

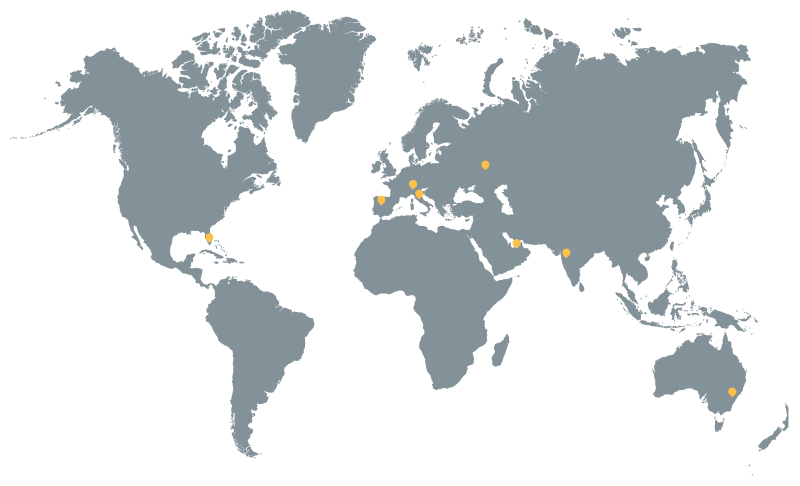

Worldwide

Headquarters and branches

Tensa - Head Office

Via Pordenone, 8 20132, Milano - ITALY

Telephone

+39 02 4300161

Fax

+39 02 48010726

TENSA - ROME OFFICE

Via Cremona, 15b 00161 Roma - ITALY

Telephone

+39 06 8084621

Fax

+39 06 8085427

TENSA - WORKSHOP

Via Buttrio, 36 33050 Pozzuolo del Friuli (UD) - ITALY

Telephone

+39 0432 6071

TENSA AMERICA LLC

1111 Kane Concourse, S.te 200 Bay Harbor Island - 33154 FL

Telephone

+1 305 8669917

TENSA INDIA - LTD, India

Malhotra Chambers, 401, 4th Floor, Off. Govandi Station Road, Deonar, Chembur Mumbai 400 088

Telephone

+91 22 49769453

TENSA RUSSIA

Butyrskaya Street 76, Building 1, 127015 Moscow Russia

Telephone

+7 495 2300024

TENSA PORTUGAL - Constr. Civil e Obras Publicas

Rua Eng. Frederico Ulrich, 3210-3 Sala 314 4470-605 Moreira de Maia

Telephone

+351 229416633

Fax

+351 229415151

TENSA AUSTRALIA

Level 1, 488 Botany Road Alexandria, NSW 2015

Telephone

+61 2 8332 6151

Fax

+61 2 8332 6101

TENSA MIDDLE EAST

RAKIA Business Center 5 Building A4, floor 12, office 1209 Ras Al Khaimah (UAE)

Telephone

+971 72432888

Our solutions

We strive to push our vast experience towards new methods and variations of applications, developing ingenious solutions for new buildings or infrastructures, as well as for the rehabilitation of the existing ones.

We value timely execution and service as keys to build long-tem relationships with our clients.